Milwaukee Indoor Signs

VIEW GALLERYWhether you operate a restaurant or a manufacturing plant, your business needs indoor signs to keep your business running smoothly. Whether your business goal is to increase your average ticket or to keep employees safe, As your local Milwaukee sign shop, Milwaukee Sign Company has the indoor signs that help you do that and more!

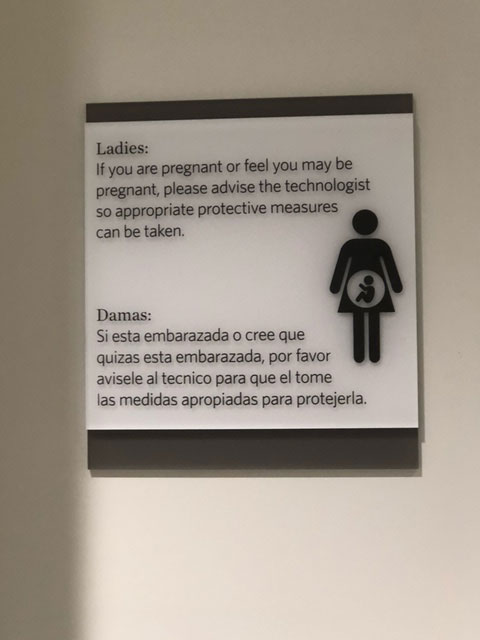

Choosing the right type of indoor signage for your business can be challenging. Many different factors need to be considered, such as your signage goals for marketing and business promotion, how guests or customers navigate your facility, any legal requirements regarding signage, and even how much wear and tear your expect your signage to experience.

As a full-service signs shop, we not only understand signage, we understand the impact signs can have on your business. From engaging customers to keeping staff safe, indoor signs play a significant role in how efficient your business runs. We focus on creating attractive, impactful signage that makes it easy for you to welcome your guests, control the flow of traffic in your facility, alert staff and visitors of potential hazards, and so much more.

Unsure what type of signs your business needs or are you ready to move into a new building? Milwaukee Sign Company provides on-site evaluations with our expert sign consultants, allowing you to speak to a knowledgeable professional who will be able to help you find and decide what signage best fits your business, brand, location, budget, and timeframe.

Call Milwaukee Sign Company at (414) 206-6733 for your Free Consultation with an Indoor Signs Expert!

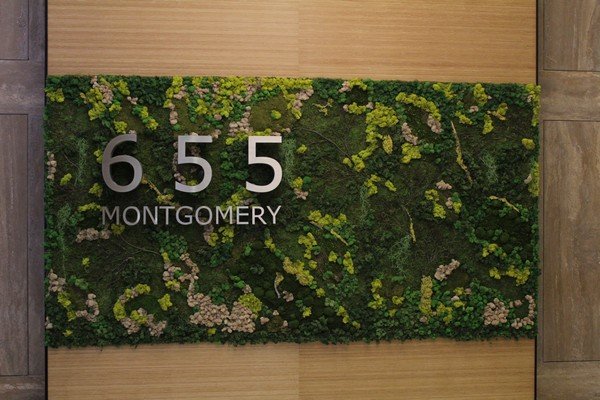

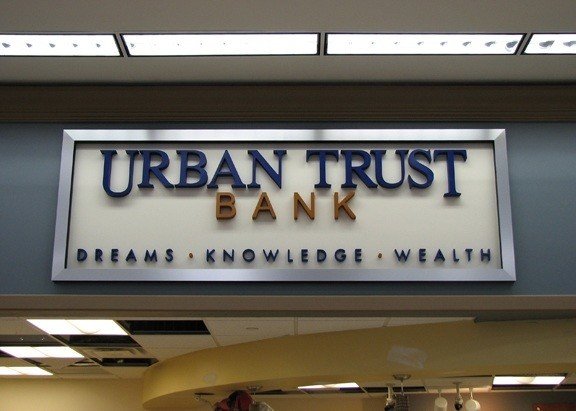

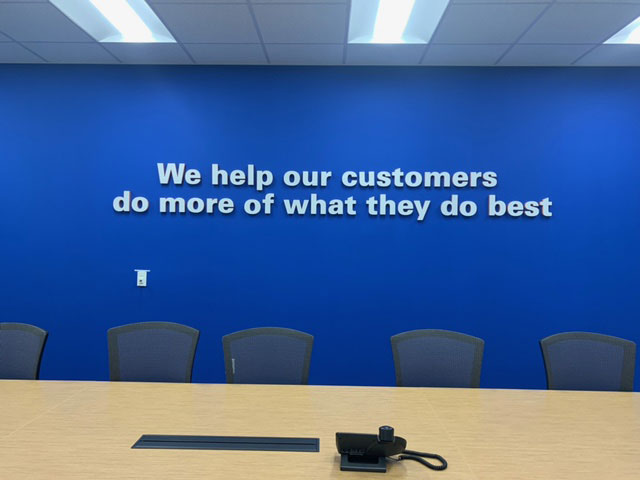

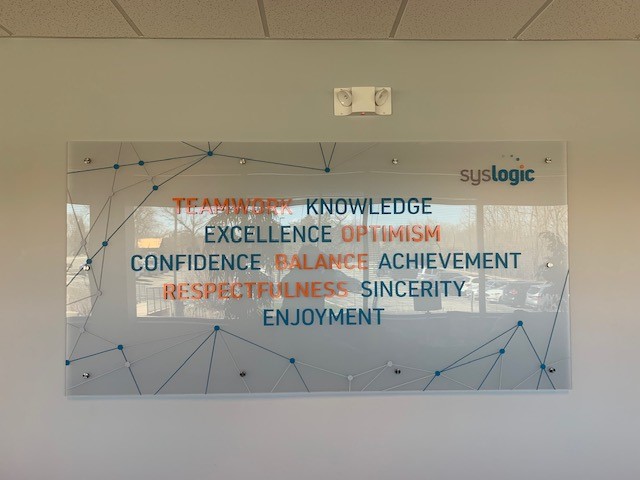

Interior Signage For Office Buildings

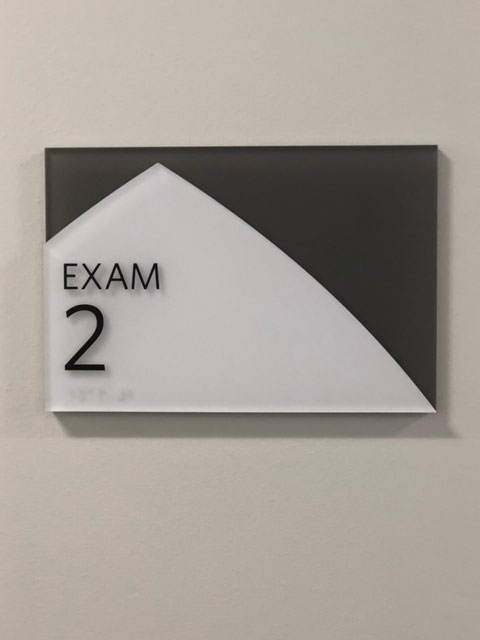

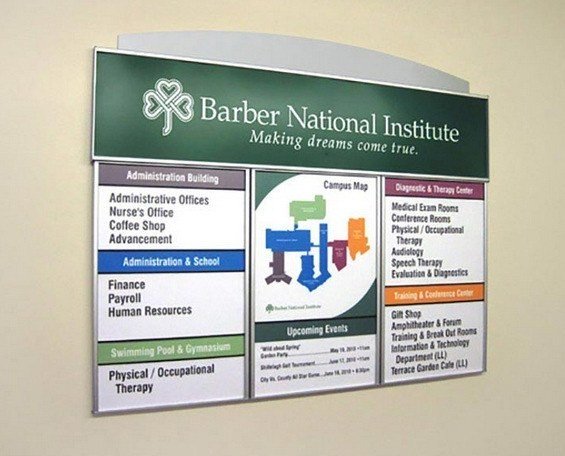

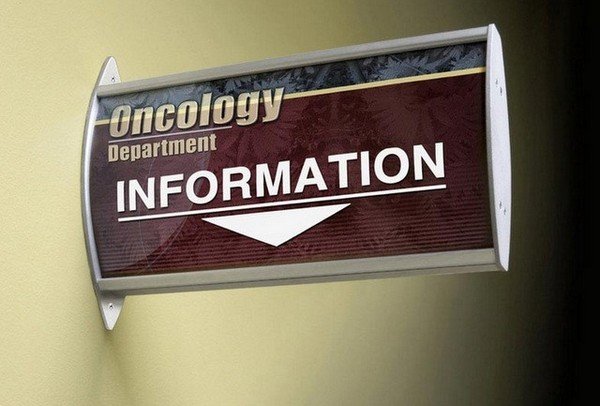

Most office complexes typically house various offices for a single company or many different businesses under one roof. Either way, this can often be confusing for first-time visitors as they attempt to navigate your facility. This usually leaves your front desk employee with the task of providing directional assistance to each new visitor, drawing their attention from more crucial tasks.

From attention-grabbing identification signs to helpful directories, indoor signage is extremely effective at providing the support your guests need when looking for the areas they want. With appropriate placement, your indoor signs will intuitively lead your visitors on their way with minimal assistance, allowing your front desk employee to focus on more critical tasks.

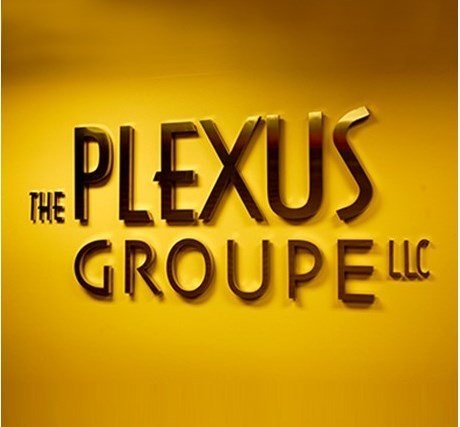

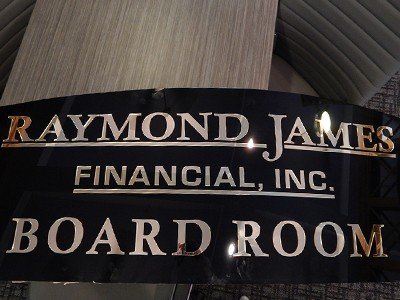

Indoor signs are also a great way to introduce and reinforce your brand throughout your entire office building. We create attractive logo signs, floor signs, large format graphics, and informational signs that not only share information about your business history but also generate the repetition needed for your brand to take hold.

Retail & Restaurant Indoor Signs

Indoor signage for retail and restaurants are more often targeted at highlighting their products rather than their brand. That doesn’t mean their branding doesn’t have a role to play in their promotional and wayfinding signage!

Milwaukee Sign Company custom designs attractive product displays, menu boards, point-of-purchase signs, hanging banners, floor vinyl, wall murals, and other custom signage that not only highlights your hottest products but also reinforces your brand by utilizing your logos, fonts, and colors. With attractive indoor signage, we make it easy for your customers to navigate your business, locate the departments and products they want, and the areas they need to do business with you. As your local Milwaukee, WI full-service sign company, we understand what your customers expect when it comes to signage, and we are committed to ensuring you meet those expectations each and every day.

Signs for Warehouses & Manufacturing

Just because your business isn’t open to the public, doesn’t mean that you don’t have a need for impactful indoor signage to keep your operations running efficiently. From reminding your staff of safe manufacturing practices to creating an enjoyable space, Milwaukee Sign Company will help you keep your business moving forward.

Large format murals, wayfinding signs, safety signs, and vinyl banners all work towards providing the support your business needs to achieve your goals of improving productivity and safety, while also creating an enjoyable workspace for your employees to return to each day. Milwaukee Sign Company is your dedicated partner for impactful manufacturing signage, providing assistance, guidance, and support to ensure you have the tools you need.

We also create eye-catching outdoor signs to help keep visitors and guests safe when arriving or leaving your facility!

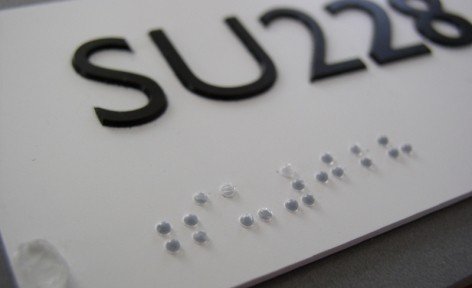

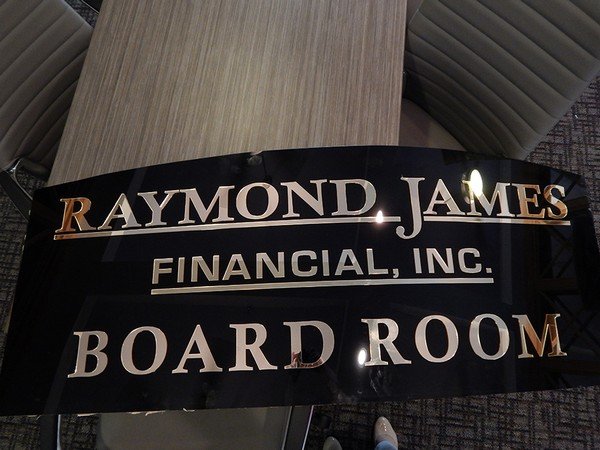

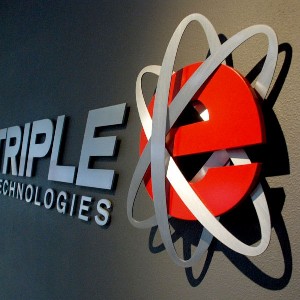

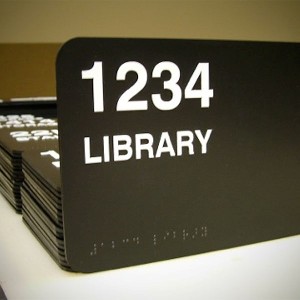

Cohesive Interior Signs for Business

Consistency is essential when promoting your business and cementing your brand as a leader within your industry. By having a solid brand guideline and referencing them in all of your marketing endeavors, you begin building the repetition needed for your brand to take hold while also creating the professional image you’ve always wanted for your business. From attention-grabbing window displays to ADA signage, lobby signs, POP signage, wayfinding signs, and other commercial signage, Milwaukee Sign Company has the tools, experience, and resources needed to deliver you the impactful signage that helps your business grow and reach new market success. We also create eye-catching vehicle wraps to brand your vehicles and help you take your brand everywhere you go!

Not sure where to start? Not a problem! Milwaukee Sign Company offers a free indoor sign consultation that allows you to speak with a knowledgeable sign professional. We listen to your thoughts and marketing goals and make the appropriate product and material recommendations based on your unique brand, business, location, budget, and timeframe. We help you understand what signage elements will best support your business and marketing goals.

Every Indoor Sign Your Business Needs!

From supporting your visitors with helpful wayfinding signage to building brand recognition, we understand the different needs of the different industries in Milwaukee. We take into consideration your location, physical space, neighboring business, and competition when creating the perfect signage that fits your brand, business, and budget.

Our indoor sign services include:

Whether you need a single vinyl graphic or an entire collection of office identification signage, Milwaukee Sign Company can create it for you.

We ensure that your signs are high-quality, attractive, and produced with environmentally sustainable methods and materials whenever possible.

Full-Service Interior Sign Manufacturers

We begin with a free sign consultation, where our knowledgeable consultants can discuss your business, brand, ideas, and needs. This insight allows us to recommend the sign products and materials that best fit your business. Once we understand exactly what you need, our graphic design team will draft a sample draft for you to review and edit as you desire. From text to logos, fonts, and colors, we will alter your project until you are completely satisfied with the end result.

After we have your approval, our fabrication team will take over the process and begin creating and prepping your indoor signage for installation. While many of our signage solutions are simple enough for a self-install, our large format graphics or complex signage are best left to the professionals for safety and technical reasons.

Free Expert Indoor Sign Consultation

Call Milwaukee Sign Company at (414) 206-6733 for your Free Consultation with an Indoor Signs Specialist!